Batteries for offshore wind vessel

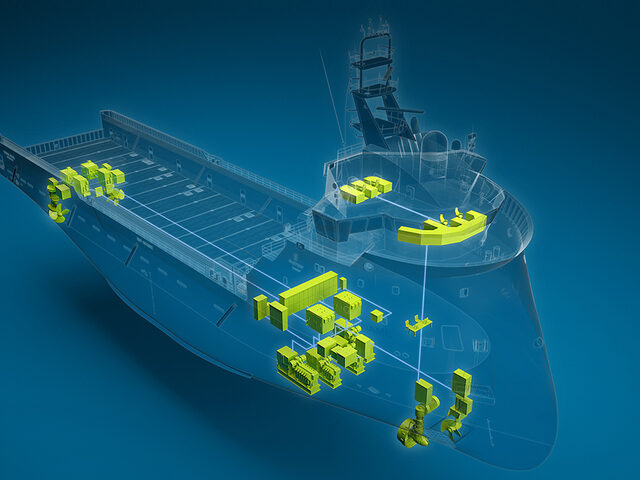

In cooperation with shipowner Bernhard Schulte, Ulstein Design & Solutions has designed a diesel-electric propulsion system assisted by batteries to reduce operating hours on the main engines, save fuel and reduce environmental footprint. The hybrid system has been installed on the WINDEA JULES VERNE at Ulstein Verft.

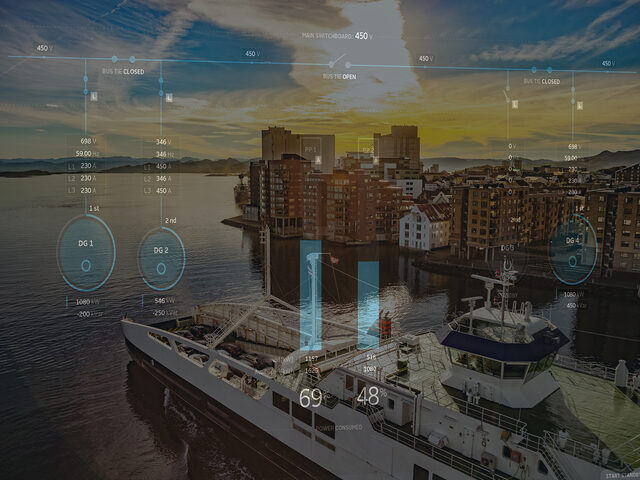

Ulstein Design & Solutions AS is responsible for the system architecture of the power package and energy management system, while Blue CTRL delivers ULSTEIN IAS™, the integrated automation system.

By installing a battery system in addition to the regular generator sets, one will be able to achieve a more even load on the generators, called peak shaving. Short-term increases of the load are handled by the battery system rather than by the generators and a comparative reduction of load will lead to a recharge of the battery system. A more even load on the generators is achieved, and energy is thus saved.

In addition, the battery system will function as a backup. This means that DP operations can be carried out with only one generator set in operation. This is fuel efficient and saves maintenance and operating hours.

The requirement for DP operations is a functionable ship even if the systems in half of the vessel fail.

Using batteries as backup will reduce the operating hours of the main engines as only one engine is in operation and not two. The on-board control systems will ensure that the power produced by the generator sets will match the power requirements, as well as ensuring that the energy stored in the batteries will be sufficient for the ship’s operations.

More about the WINDEA JULES VERNE offshore wind vessel for Bernhard Schulte.

Please contact us for more information

Companies

-

Ulstein Design & Solutions AS

P. O. Box 278,

Tel: +47 7000 8000

NO-6067 Ulsteinvik

Norway -

Blue Ctrl AS

Lerstadveien 545

Tel: +47 481 24 400

6018 Ålesund