Big opportunities in offshore wind

Published

The development of European offshore wind farms has surged over the years and turbine sizes have increased much quicker than expected. To deal with these developments and make renewable energy production even more competitive, turbine installation ships must follow the evolution.

The development of European offshore wind farms has surged over the years and have been an example for offshore wind projects in other parts of the world. At the same time, turbine sizes have developed much quicker than expected to what is now considered as the next generation of 12-15 MW turbines. To deal with these developments and make renewable energy production even more competitive, turbine installation ships must also be cost-effective.

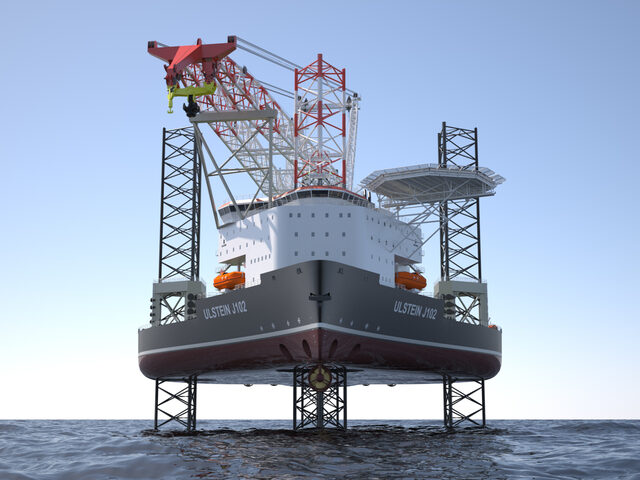

The X-JACK heavy lift jack-up series is Ulstein’s answer to contribute to a significant efficiency gain in windfarm installation.

The ULSTEIN J102, the midsize version of the ULSTEIN X-JACK series, is believed to be the closest one can get to an optimal yet cost effective jack-up design for wind turbine installation. Using a high capacity crane of upto 2,500 t and 160m hook height above deck, the design will allow contractors to install 15 MW wind turbines with the same efficiency as currently used for installing 8 MW units.

Scaling-up conventional heavy lift jack-up vessel designs proves challenging due to the disproportional weight increase compared to gain in Variable Deck Load (VDL). This has created uncertainty with turbine manufacturers, wind farm operators and installation contractors on how to install the future generation wind turbines.

Therefore, Ulstein started to work with what is considered the optimal jack-up design, a square platform with the legs spaced out as much as possible. By rotating the optimum jack-up design 45 degrees, a natural bow shape is provided, with two legs and the crane on vessel centre line. One leg is placed in the bow and aft, and one on either of the ship sides.

This led to what is key in ULSTEIN’s design: its patented cruciform lay-out, which results in a very strong, yet simple primary structure. Not only does it generate significant weight savings of 10-15% compared to conventional jack-up designs having similar capacities, it also allows preloading operations to be performed without any hull torsion. It is this game changing design innovation that creates heavy lift and cargo capabilities well beyond any existing jack-up design and make ULSTEIN’s 4th generation jack-up vessel design well suited to enable operators to take the next step in developing offshore wind farms.

The global offshore wind market is expected to grow annually by 19% upto 2023. Key in this market growth is the change in energy mix, where increased energy demand results from a.o. a growing global population and rise in income in developing countries.

(Source: Global Offshore Wind Market Report 2018, NORWEP).

The development of the ULSTEIN X-JACK series is a logical next step in Ulstein Group’s strategy to reduce cost in the production of renewable wind energy, and to become a leading company in supporting the offshore wind industry with more efficient assets.