What makes vessel conversions a sustainable option?

Shipping companies regularly choose conversions to secure existing vessels a new life in another segment which increases the competitiveness of the tonnage. Why is this a sustainable choice?

Conversion projects of offshore Oil & Gas vessels are in demand. On a global basis, an average of 180 vessels are being converted each year. The majority of these conversions are related to tankers and general dry cargo vessels, however, the conversions of offshore vessels have increased after 2014, as a consequence of the downturn of the Oil & Gas market.

The conversion projects are an alternative to achieving competitive and more sustainable tonnage that can be available faster and at a lower cost than newbuilds. Conversions result in substantial CO2 emission savings due to the reuse of existing tonnage. Platform supply vessels (PSV) are one of the single largest sources of conversions of offshore vessels in the last five years.

Additional read - The flexibility of the PX121 design:

Conversion of the PSV 'Farland' to a Service Operation Vessel for Offshore Wind.

Three reasons why PSVs are great conversion assets:

PSVs are a good platform for many conversion applications primarily for three reasons.

Firstly,

most of the vessels have sufficient energy generating capacity to cater for the additional demand of the new functionality. Thus, most likely, there is no need to make a major adjustment to the power plant, which would require major investments with regard to time and money.

Secondly,

the vessels are arranged with a large open deck. This means that additional functionality can be easily implemented on the top of the aft deck without requiring changes to the structural hull.

Thirdly,

most of the tonnage built for operations in the North Sea have been built with high-quality standards (a large portion of the fleet is featured with ice class 1C), which secure a long lifetime of the vessels.

Business strength and an environmental benefit

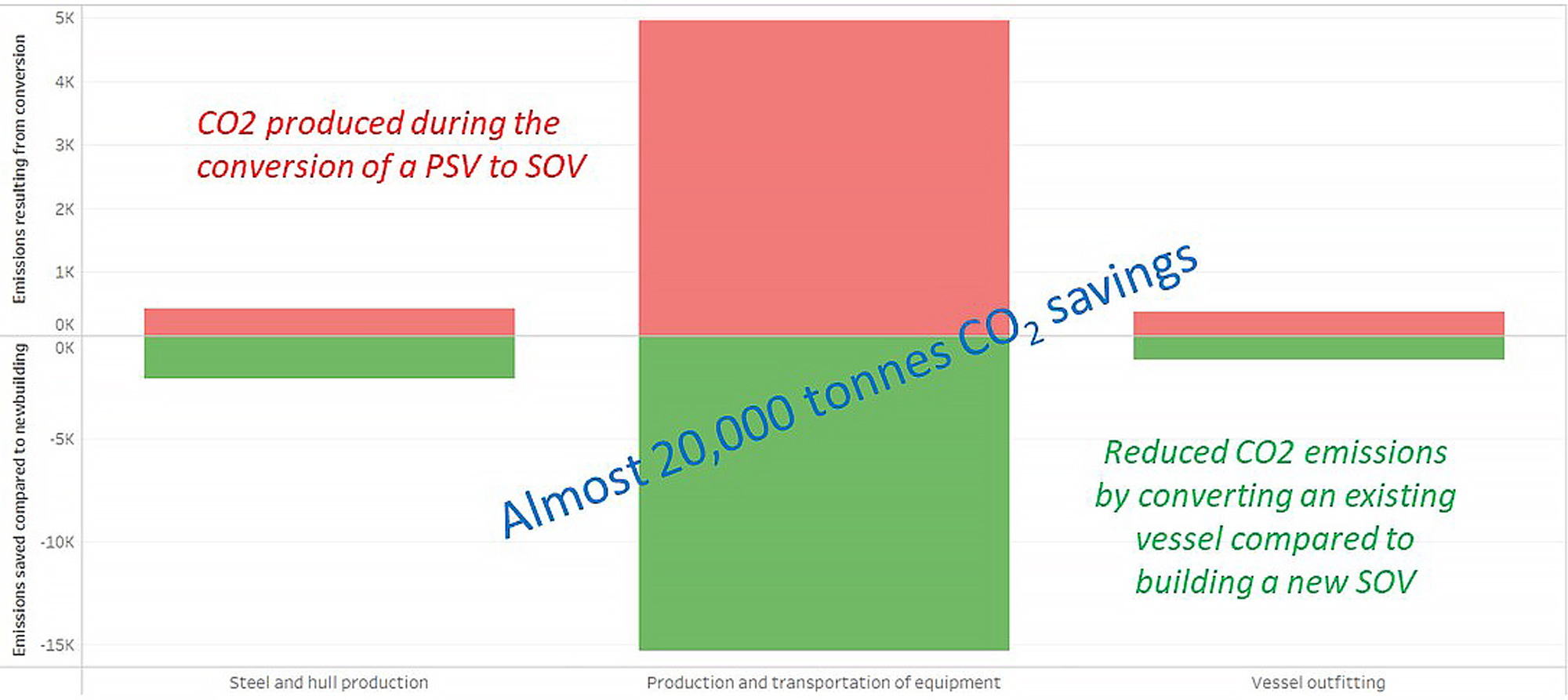

Giving a second life to existing tonnage does not only represent a business strength (typically lower cost and shorter lead time than newbuilds), but also an environmental benefit. The environmental benefits range from the CO2 emissions generated during the production of the vessel, the production and transportation of systems and equipment on board, and the final recirculation of the vessel. It has also an impact on reducing visual and local contamination, as some areas have accumulated laid-up tonnage that is rusting.

Massive reductions in CO2 emissions

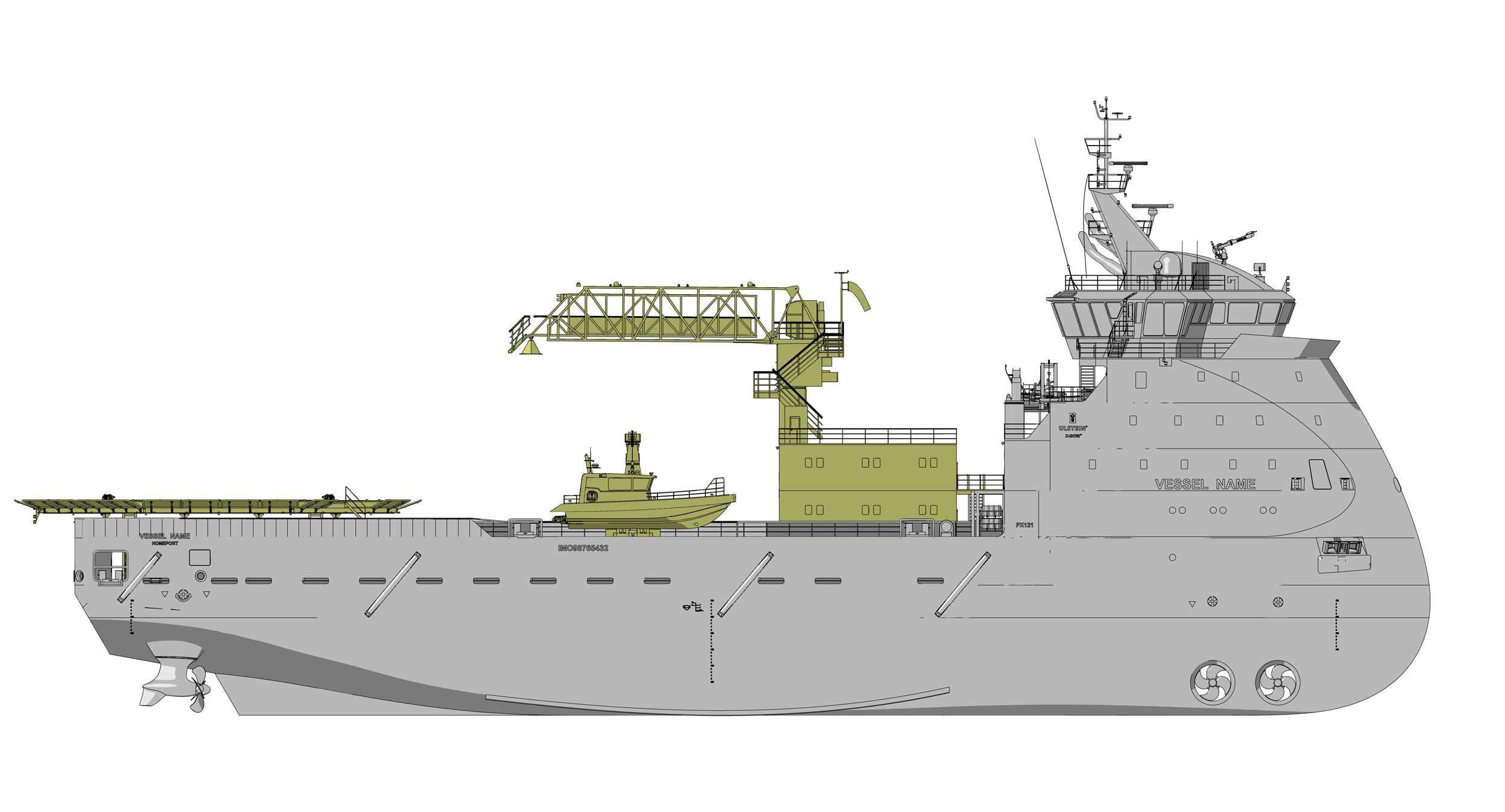

There is a large potential in the conversion of Platform Supply Vessels due to their energy generation capacities, open deck, and high-quality standards. Also, a conversion of a Platform Supply Vessel to e.g., a Service Operation Vessel, can lead to large CO2 savings compared to newbuilds.

The total CO2 emissions produced when converting a Platform Supply Vessel to an Offshore Wind Service Operation Vessel (SOV) are estimated to be in the range of 5,500 to 6,000 tonnes. Based on the characteristics of the base ship, the conversion can range from the installation of a gangway to perform personnel transfers, to the installation of new cabins, removal of underdeck storage tanks, or installation of energy storage systems. It is likely that the conversion of a PSV will require adding additional cabins and public spaces, since the people onboard capacity (POB) of service operation vessels (SOV) is 3 to 4 times larger than that of PSVs.

An SOV newbuild will, however, lead to the emission of 20,000 to 25,000 tonnes of CO2 during its production, where the largest source is the production and transportation of equipment and components in the vessel.

As a result, the conversion leads to more than 15,000 tonnes of CO2 savings, and these savings are equivalent to the CO2 emissions of the vessel operating during a 3-year period.

The converted vessel will therefore have a lower lifecycle footprint even if it is used for 30 years compared to a purpose-built newbuild vessel.

In this example, the estimated numbers are based on a generic conversion and the actual emissions for a particular vessel will vary. Nonetheless, the numbers are apparent, the best approach for the environment is to prolong the life of your stocked vessel with an upgrade to new segments. With up-to-date environmental-friendly power solutions, the vessel will be a fully competitive asset to your fleet within the time span of a few months.

Conversion projects can be further enhanced by the implementation of alternative energy technologies such as batteries.

Project management and design expertise

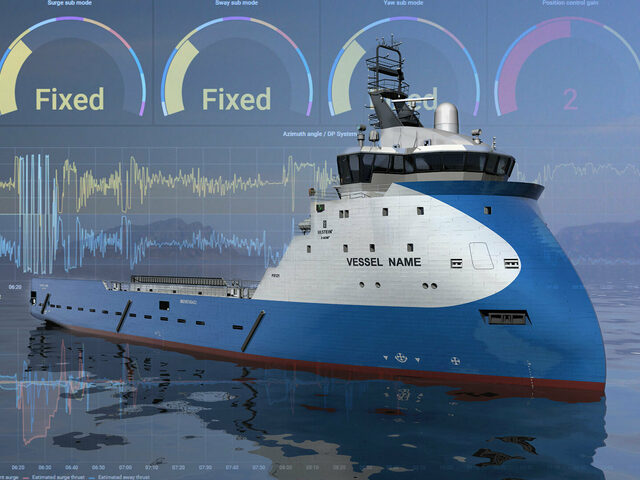

The design, project planning and execution are very important factors to consider for successful conversion projects. Ulstein Group, with our experience in the design, construction and service of more than 100 offshore vessels is firmly positioned to evaluate, develop and execute conversion projects.

Please contact us for more information

Companies

-

Ulstein Design & Solutions AS

P. O. Box 278,

Tel: +47 7000 8000

NO-6067 Ulsteinvik

Norway -

Ulstein Verft AS

P. O. Box 158,

Tel: +47 7000 8000

NO-6067 Ulsteinvik

Norway