The ECOFIVE concept for sustainable fishing

ECOFIVE is a concept for fishing vessels where the goal is to utilise 100 per cent of the catch, minimise quality losses during handling and reduce energy consumption. Bluewild’s next factory trawler will be the first fishing vessel to use ECOFIVE with, a.o., a newly developed method for taking the catch onboard.

“ECOFIVE is an abbreviation for "Eco-friendly Fishing Vessel", and has been developed by the team in the fishing company Bluewild in Ålesund, Norway. Ulstein took on the challenge of designing the maritime platform where the goals in ECOFIVE can be realised”, says Erwin Jager, sales manager fisheries at Ulstein Design & Solutions AS.

“To avoid large quality losses during the handling and intermediate storage of the catch, Ulstein has developed a new and innovative concept where the catch will flow into the storage tanks from below the waterline.”

Fishing vessels for a greener future

The ECOFIVE concept focuses on utilising resources so that nothing is lost from the catch and with minimal use of energy. The main product, the by-products and residual raw materials will be of very high quality.

“Great emphasis has been placed on fish welfare and high quality of the raw material. The resources are limited, and we will ensure zero emissions of the residual raw material”, says Tore Roaldsnes, managing director at Bluewild.

“An increase in the quality of the fish product can be achieved by careful handling of the catch, by avoiding squeezing and pressure, and by storing the catch alive until production. The better quality has been solved through a new gentle reception solution for the catch that is better adapted for live storage and with an optimised flow of the catch into the factory. We have also worked to increase the factory area on board so that there is sufficient space for processing the high-quality catch, the remaining catch and treatment of the residual raw material”, he emphasizes.

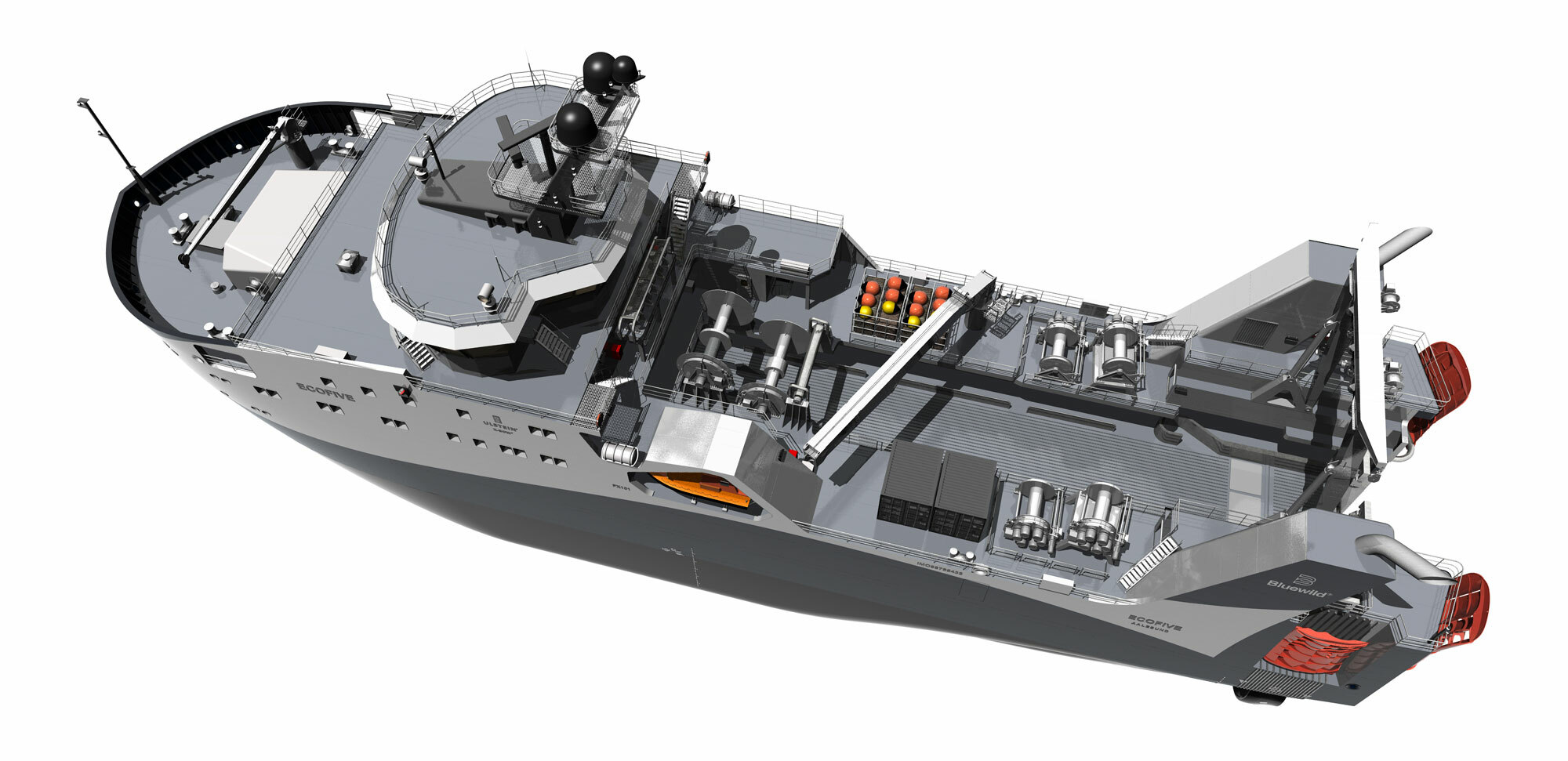

How the ECOFIVE concept is implemented on the ULSTEIN FX101 factory trawler

• Gentle handling system

A handling system for the trawl directs the fish into water-filled live storage tanks in the vessel below the waterline. The catch does not leave the water and is thus not exposed to the same physical stresses or degradation as compared to hauling a trawl over the stern ramp before emptying the catch into dry receiving bins.

• Live storage

The quality of the end product will be significantly higher when the catch arrives alive at the factory before bleeding. In the aft live storage tanks, fish and shrimp can be kept alive as a result of controlled water exchange, oxygen supply and temperature control. In the live storage tanks, the catch is controlled and will be brought to the upper factory deck by overpressure release. The typical damage to the catch that can occur when using negative pressure pumping will thus be avoided.

• Steady use of the factory

As the catch stays alive for a longer period in the receiving tanks, the factory can work steadily with smaller variations in production rates. The factory orders catch from the receiving tanks when it has available capacity, and without loss of quality that follows when the catch is kept in dry receiving tanks.

• Processing of several product types

The factory can produce fillets from whitefish, cooked and single-frozen consumer prawns or deliver raw prawns frozen in blocks for further production on land.

• CO2 for freezing

After bleeding, the fish will pass through cooling pipes to lower the temperature of the fish, which contributes to improved bleeding and faster freezing. CO2 gas will be used for the freezing plant. In addition to being a safe alternative, the temperatures can be kept far lower, down to -35 degrees Celsius, and thus, more efficient freezing. It improves energy efficiency and helps to ensure product quality.

• Residual processing

All the residual raw material will be taken care of, in such a way that it can be raw material also for human consumption. With a separate process for the by-catch, the cut-off will be separated from and frozen in blocks, the same happens with the head, back and tail, while the entrails will be used in the production of unoxidized oil in a low-temperature process. Improved warehouse logistics with sorting and zone storage across the two levels in the freezer room will make this efficient.

Large energy savings in seafood production

“We want to achieve the highest possible quality of the fish product and a versatile production line for differentiated products; fillet, cooked shrimp and frozen. Due to the efficient processing, there will also be a significant reduction in energy consumption and emissions per unit of fish product produced”, says Roaldsnes.

Reduced power consumption when trawling

Another aspect of the ECOFIVE concept lies in the development of the ship design and system architecture. The diesel-electric / diesel-mechanical hybrid system has two large propellers for maximum efficiency during trawling. The battery energy storage system facilitates peak shaving and trawl spinning reserve. Taking into account the vessel’s overall operational profile, the optimised hull, the propeller and rudder system that maintains efficiency through all operations and the hybrid power system with batteries as supporting power source, energy consumption and emissions will be reduced by at least 25 per cent and in some cases more than 40 per cent during trawling and production.

“The ECOFIVE concept can make the entire fishing fleet greener”

All or part of the ECOFIVE concept can also be used by other fishing vessel owners. “We all need to do our part to make the fishing fleet greener, and the design technology solutions from the ULSTEIN FX101 concept can be used to achieve this”, Tore Roaldsnes concludes.

Please contact us for more information